PRODUCTION TECHNOLOGY DEVELOPED

Sustainable intensification of conventional rice-wheat and maize-wheat rotations with summer mungbeanin IGP region for higher productivity and restoration of soil health

| S. No. | Title | Production Technology 1 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the Research & Technologies developed during the last five years: | Sustainable intensification of conventional rice-wheat and maize-wheat rotations with summer mungbeanin IGP region for higher productivity and restoration of soil health |

| 3 | Salient feature of the Research/Technology: | Based on 18 years old long-term study at ICAR-IIPR, Kanpur, continuous practice of rice-wheat-mungbean (R-W-Mb) and maize-wheat-mungbean (M-W-Mb) have substantially improved the yields of cereal crops (rice, wheat and maize), system productivity, soil nutrient availability, soil biological properties and carbon sequestration.Growing of extra-early summer mungbean (cv. ‘Virat’ with maturity duration 52-55 days) increased system productivity, profitability, and enhanced C-sequestration, soil physical properties, microbial activity and diversity over cereals system (rice-wheat and maize-wheat).Summer mungbean with seed rate of 20 kg/ha after harvesting wheat with 100 kg DAP/ha in conventional tilled condition with post-emergence herbicide application of imazethapyrat 80 g a.i./ha with 3-4 irrigations can enhance yield and income over best management practice and farmers practice of continuous rice-wheat and maize-wheat with summer fallow. Rice-wheat-mungbean and maize-wheat-mungbean (M-W-Mb) increased 18.9% and 15.1% higher total organic carbon (TOC) than R-W and M-W, respectively.These systems increased 22.4% and 14.1% higher carbon management index (14.1-22.4%) than R-W and M-W, respectively.Maize-wheat-mungbean increased the activity of alkaline phosphatase (20%), arylsulfatase (16%), β-glucosidase (9%), dehydrogenase (52%) and protease (5%) than M-W. Likewise, rice-wheat-mungbean rotation increased soil enzymes activities: arylsulfatase (41%), dehydrogenase (38%), and phosphatases (32%). Rice-chickpea rotation had higher alkaline phosphatase (10%), β-glucosidase (13%), and protease (6%) activities over R-W. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. Narendra Kumar, Principal Scientist &Head,Division of Crop Production, contact no. +91 9695241110, narendra.kumar1@icar.gov.in

Dr. C. P. Nath, Scientist, contact no. +91 9474670414, CP.Nath@icar.gov.in |

| 5 | How this technology contributed to agricultural advancements or improved farmer practices: | These intensive pulse-inclusive cropping systems led to higher productivity over the conventional practice of the predominant cereal-cereal systems (such as rice-wheat and maize-wheat) and also resulted in positive changes in soil quality (higher soil organic carbon) with reduced use of resources. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | This technology has been disseminated through demonstration at five villages Kharauli, Karchalpur, Khadra, Mirai, and Delmau (Deomai Block, Fatehpur district) and two villages, Maronda and MarondaSuchit (Unnao District) of Uttar Pradesh under Farmer FIRST programme of ICAR and SC-SP plans. It covered 550 farmers in 178 ha in Fatehpur district after introducing this technology, whereas before 2019-20, the area was 3.50 ha only. The recommendation domain of this technology could be rice-wheat and maize-wheat systems in the North-western IGPs. This summer mungbean intervention was a success story of Farmer FIRST programme and published in IIPR-newsletter. |

| 7 | Any other Information: |

Demonstration of summer mungbean ‘Virat’ at Karchalpur village in Fatehpur district of U.P.

|

Zero-till residue management in post-rainy seasons after puddled rice and rice-wheat crop diversification with pulses for reduction of weeds, enhancing crop productivity and soil quality

| S. No. | Title | Production Technology 2 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024,Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Zero-till residue management in post-rainy seasons after puddled rice and rice-wheat crop diversification with pulses for reduction of weeds, enhancing crop productivity and soil quality |

| 3 | Salient feature of the Research/Technology | In the rice dominating areas of India (Indo-Gangetic plains), farmers are not leaving puddled transplanted rice (PTR) because of assured higher yield and less weed infestation than zero tilled (ZT) direct seeded rice (DSR). Considering this, partial zero-tillage based residue management production of post rainy season crops were evaluated in a nine years station trial and further validation of the results in the year 2021-2022. The study []recommended Conventionalpuddled transplanted rice followed byzero till wheat with 5 t/ha rice residues retention followed byzero till summer mungbean (variety ‘Virat’) + 5 t/ha wheat residues retention had considerable yield advantage (higher system productivity), soil quality (P and K availability), and higher SOC sequestration over conventional practice of rice-wheat production system. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. Narendra Kumar, Principal Scientist & Head,Division of Crop Production, contact no. +91 9695241110, narendra.kumar1@icar.gov.inDr. C. P. Nath, Scientist, contact no. +91 9474670414, CP.Nath@icar.gov.in |

| 5 | How this technology contributed to agricultural advancements or improved farmer practices: |

ZT in post-rice seasons were introduced in farmer’s fields after technology refinement at ICAR-IIPR, Kanpur. The sowing of wheat and mungbean were done in ZT condition after a presowing irrigation after harvesting of rice & ZT wheat, respectively. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: |

Rice– wheat (R–W) rotation is being practiced in 13.5 m ha area in the Indo–Gangetic Plains (IGP) of South East Asia. Decline in rice and system productivity and soil biological functions under conventional–till pudddled transplanted rice (CT rice) followed by intensive tillage in wheat is posing a serious concern in these regions. In the rice dominating areas of India (Indo-Gangetic plains), farmers are not leaving puddled transplanted rice (PTR) because of assured higher yield and less weed infestation than zero tilled (ZT) direct seeded rice (DSR). Conventional tilled wheat and summer mungbean results in increased costs of cultivation and delayed sowing due to less turn around period. Therefore, zero-tilled wheat and short duration summer mungbean can be best fitted in the rice-wheat-mungbean system keeping PTR in place |

| 7 | Any other Information: | This technology is also tested under AICRP and recommended for different agro-ecologies of the country.

|

Diversification of maize-wheat system of IGP with pulses (chickpea/mungbean) to reduce dominant weeds (above-ground and soil seedbank) and ecological weed

management

| S. No |

Title | Production Technology 3 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Diversification of maize-wheat system of IGP with pulses (chickpea/mungbean) to reduce dominant weeds (above-ground and soil seedbank) and ecological weed management |

| 3 | Salient feature of the Research/Technology | Ecological weed management is an important aspect of integrated weed management in agro-ecosystem.Assessment and monitoring of weed seed density/seedbank in soil and its diversity provides an insight of dominant weed flora in agroecology.Diversified pulse-based crop rotations can interrupt the life cycle of annual weeds and alter community composition and diversity of weed seedbank and above-ground weed flora however less studied. The concept is: crop diversification with maize (variety ‘DKC 9108’) – wheat (‘HD 2967’) – mungbean (‘Virat’) (M-W-Mb) system with application of atrazine 1 kg a.i./ha at 12–15 days after sowing (DAS), sulfosulfuron + metsulfuron methyl 40 g/ha (product basis) at 25 DAS in wheat and imazethpyr 100 g/ha at 25 DAS in mungbean with 120:60:40 kg/ha of NPK in maize, wheat and 20:60:40 kg/ha NPK for mungbean for reducing weed seed density and above-ground weeds over maize-wheat (M–W). Legume inclusion/diversification resulted in a more even weed community than the M–W rotation. It is an ecological principle that increased weed diversity is beneficial agronomicallly and environmentally, irrespective of the weed species. Theoretically, higher weed diversity is subjected to less competitive weeds because of reduced chance of resistance development and less dominance of few highly competitive weeds (such as Phalaris minor and Avenaludoviciana) in cereal systems of IGP. The diversified weed communities reduced the negative impact of competitive and dominant species on productivity, while enhancing agricultural sustainability. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. C. P. Nath, Scientist, contact no. +91 9474670414, CP.Nath@icar.gov.in

Dr. Narendra Kumar, Principal scientist &Head,Division of Crop Production, Contact no. +91 9695241110, narendra.kumar1@icar.gov.in |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | The recorded yield of maize in farmer field was 5.3 t/ha (variety ‘DKC 9108’) compared to local variety (4.2 t/ha) with a yield increase of 23%. Under farmer’s field demonstration, average yield of chickpea recorded was 26.8 q/ha and additional income gained INR 13769/ha under R-C than R-W. The R-C system was demonstrated in Khadra, Karchalpur and Mirai villages of Fatehpur district of Uttar Pradesh by covering 71 farmers covering 5.55 ha area.Major weed species in seedbank based on the relative density included Leptochloachinensis(11.4%), Dactylocteniumaegyptium(8.6%), Eleusineindica(7.4%), Digitariasanguinalis (4.2%), Coronopusdidymus(11.8%), Melilotusindicus(7.7%),Anagallisarvensis(10.2%),Phyllanthusniruri(13.7%), and Portulacaoleracea(5.9%). Thesespecies together accounted for 81% of total weed seedlings emerged in the whole (0–15 cm) seedbank, irrespective of treatments. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | This technology is demonstrated in Fatehpur district of Uttar Pradesh and showed superiority over existing maize-wheat system in terms of economics and productivity. The effect of |

| 7 | Any other Information: |

|

Topramezone a new generation herbicide for efficient post-emergence weed control in chickpea

| S. No. |

Title | Production Technology 4 | |

|---|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production | |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh | |

| 2 | Title of the research & technology developed during the last five years | Topramezone a new generation herbicide for efficient post-emergence weed control in chickpea | |

| 3 | Salient feature of the Research/Technology | The research aimed to identify and subsequently standardize the dose of alternative new-generation post emergence herbicide(s) in chickpea for efficient weed control and improving productivity. Based on a five year experiments, the experimental results conclude that Topramezone, a post emergence herbicide with soluble concentrate formulation, could be effectively control broad spectrum weeds in chickpea using the application of 20.6 ml a.i./ha. Topramezone mode of action includes ‘4 Hydroxyphenylpyruvate dioxygenase (HPPD) inhibitors’ that ultimately inhibit the plastoquinone biosynthesis in plants. The herbicide has been therefore recommended for selective use in chickpea crop without any phytotoxicity. Iteffectively controlled broad-leaved weeds such as Chenopodium album, Lepidium didymium, Spergulaarvensis, Medicagopolymorpha, Melilotusindicus and grassy weed Cynodondactylon and Digitariasangunalisin chickpea. It is the first-time report of broad-spectrum herbicide that can control both broad-leaved and narrow-leaved weeds in chickpea as post-emergence application. | |

| 4 | Developed by (Name / Designation / Contact No./Email ld) |

|

|

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | The yield advantage with topramezone was 19.6% (mean of two years) than the recommended herbicide pendimethalin – quizalofop-p-ethyl (P≤0.05).It achieved a weed control efficiency of 78-83% in field testing which was higher over present recommendation (pendimethalin 1000 g a.i./ha – quizalofop-p-ethyl 100 g a.i./ha) (mean of 7 years). Chickpea seed yield was increased by 15.3-19.6% with topramezone than pendimethalin 1000 g a.i./ha – quizalofop-p-ethyl 100 g a.i./ha (current recommendation). Large-plot demonstration at ICAR-IIPR, Kanpur recorded yield of 2.11 t/ha (Control plot yield: 0.63 t/ha) with variety ‘JG 16’.This herbicide reduced total weed density by 68-70% at 45 DAS over weedy check.It reduced cost of cultivation by INR 3630 for reduction in labour with single time application of POST rather two times application of pendimethalin 1000 g a.i./ha – quizalofop-p-ethyl 100 g a.i./ha and time by two man-days. Topramezone 20.6 g a.i. ha-1 gave additional net returns of INR 29237.8 over pendimethalin – quizalofop-p-ethyl (current recommendation).It also gave higher B:C ratio of 2.37 over pendimethalin – quizalofop-p-ethyl of 1.97. | |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | The herbicide has been tested in 10 locations through AICRP in diversified ecologies such as Durgapura, Ludhiana, Shillongani, Dholi, Imphal, Kalyani, Ranchi, Raipur Badnapur, Kalaburagi of the country. Topramezone has shown very effective against all kinds of weeds in chickpea with weed control efficiency of >80%. Demonstration at farmers’ fields in Uttar Pradesh also showed similar results. | |

| 7 | Any other Information: |

Large plot demonstration of topramezone 20.6 g a.i./ha |

Clodinafop-propargyl+Na-acifluorfen a new generation post-emergence ready-mix herbicide for selective weed control in mungbean

| S. No. | Title | Production Technology 5 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Clodinafop-propargyl+Na-acifluorfen a new generation post-emergence ready-mix herbicide for selective weed control in mungbean |

| 3 | Salient feature of the Research/Technology | mungbean as POST. However, resistance development of imazethapyr is reported with poor weed control. The research aimed to identify and subsequently standardize the dose of alternative post emergence herbicide(s) in rainy season mungbean for efficient weed control and improving crop productivity. Based on a five year experiments, the experimental results conclude that A ready-mix clodinafoppropargyl + sodium-acifluorfenwith Emulsified concentrate (EC) formulation, could be selectively applid for broad spectrum weed control in mungbean using the application of 187.5 g a.i. ha-1. The herbicide has been therefore recommended for selective use in mungbean crop without any phytotoxicity. A long-standing demand of farmers and policy-maker is to have a POST herbicide for mungbean. Our idea was to sort out this POST herbicide from the available herbicide recommended in other crops. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. C. P. Nath, Scientist, contact no. +91 9474670414, CP.Nath@icar.gov.inDr. Narendra Kumar, Principal scientist & Head,Division of Crop Production, contact no. +91 9695241110, narendra.kumar1@icar.gov.inDr. K. K. Hazra, Scientist (Agronomy), contact no. +918953455970, Kali.Hazra@gmail.com |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | This herbicidecontrolled weeds such as Trianthemaportulacastrum, Digeraarvensis, Amaranthusviridis, EleusineindicaandDigitariasangunalis. It achieved the weed control efficiency of 76-84% over years. It increased mungbean yield by 37.6% than imazethapyr 100 g a.i./ha(current recommendation). Large-plot demonstration at ICAR-IIPR, Kanpur recorded yield of 1.28 t/ha over control (yield 0.72 t/ha). It is a novel post-emergence ready-mix herbicide that can control both broad-leaved and narrow-leaved weeds in mungbean both in summer and rainy seasons. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | The herbicide has been tested through AICRP on MULLaRP for 3 years Kota, Mandor, Akola, Raipur, Berhampur, S K Nagar and Hisar.Clodinafop-propargyl + sodiumacifluorfenwas effective across regions with control efficiency of 82-85% in different ecologies and higher productivity.Similar results were also recorded at farmer’s fields with yield advantage of up to 30%. |

| 7 | Any other Information: |

Large plot demonstration of clodinafop-propargyl + sodiumacifluorfen 187.5 ml a.i./ha |

Integrated management of Cyperus rotundus (Nutsedge)

| S. No. | Title | Production Technology 6 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Integrated management of Cyperus rotundus (Nutsedge) |

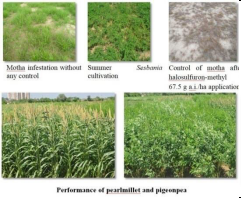

| 3 | Salient feature of the Research/Technology | The detail package of practices developed for effective control Cyperusrotundus (Nutsedge) are Summer Sesbania (seed rate 20 kg/ ha) + 2,4-D @ 0.5 kg a.i./ha in summer for reducing Cyperusrotundus in cereal-pulse systems, stale bed technique during summer with irrigation Halosulfuron methyl @ 70 g a.i./ha.

The recommendation is based on a three year field study conducted at ICAR-IIPR in pulse based cropping system (pigeonpea-wheat and pearlmillet- chickpea systems). Technology to control purple nutsedge was developed employing crop rotation, stale bed techniques and herbicides |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. C. P. Nath, Scientist, contact no. +91 9474670414, CP.Nath@icar.gov.in

Dr. Narendra Kumar, Principal scientist &Head,Division of Crop Production, contact no. +91 9695241110, narendra.kumar1@icar.gov.in Dr. K. K. Hazra, Scientist (Agronomy), contact no. +91 8953455970, Kali.Hazra@gmail.com |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | Summer mungbean cultivation increased motha (Cyperusrotundus) infestation in subsequent rainy season crops (pearl millet and pigeonpea). Irrigation – halosulfuron-methyl (70 WG) 67.5 ga.i./ha reduced motha and total weed density over summer fallow situation. It resulted in significantly higher pearlmillet (3.74 t/ha) and pigeonpea (1.41 t/ha) yields at third year of cropping cycle over summer fallow situation. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | The advantage of stale seed bed is already reported by many researchers. But, use of halosulfuran along with stale seed bed has shown greater advantage over other practices followed to control motha. Further, green manuring during summer fallow has shown added advantage. |

| 7 | Any other Information: |

|

Conservation tillage and weed management module in rice-chickpea cropping system in IGP region

| S. No. | Title | Production Technology 7 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Conservation tillage and weed management module in rice-chickpea cropping system in IGP region |

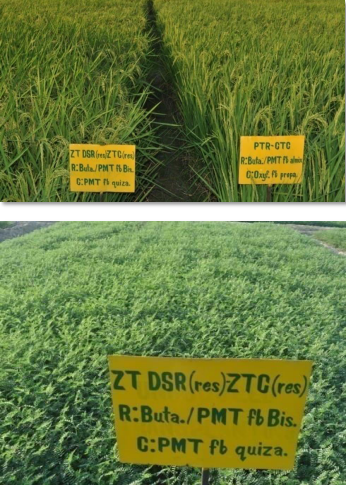

| 3 | Salient feature of the Research/Technology | The recommended improved crop management practices are an outcome of a five-year (2016-2021) field-based experiment at ICAR-IIPR, Kanpur. The detail package of practices include zero till direct seeded rice followed by zero till chickpea (20 cm standing stubble) and weed management through pre emergence (Oxyfluorfen at 150 g active ingredient/ha) and post emergence (Popaquizafop 100 g active ingredient/ha) for higher weed control efficiency and crop productivity of rice-chickpea system. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. C. P. Nath, Scientist, contact no. +91 9474670414, CP.Nath@icar.gov.in

Dr. Narendra Kumar, Principal scientist &Head,Division of Crop Production, contact no. +91 9695241110, narendra.kumar1@icar.gov.in Dr. K. K. Hazra, Scientist (Agronomy), contact no. +91 8953455970, Kali.Hazra@gmail.com |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | The treatment zero till direct seeded rice followed by zero till chickpea increased rice and chickpea yields over the conventional puddled transplanted rice followed by conventional till chickpea system. Pendimethalin 1.0 kg a.i./ha (PE)-bispyribac sodium 20 ga.i./ha at 20 DAS (POE) in rice and oxyflurofen 150 ga.i./ha (PE) propaquizafop 100 g a.i./ha at 25 DAS (POE) in chickpea resulted in reduced weed density in system and gave significantly higher yields. ZTDSR-ZT had increasing yield trend over the years with higher SYI of rice, chickpea and system which is important in the IGP. The treatments CTDSR-CT and ZTDSR-ZT led to a significantly higher net returns and benefit-cost ratio over PTR-CTC. Additional benefit of 35,000- 40,000 was achieved with the treatments ZIDSR-ZT over PTR-CTC.

Treatment zero till direct seeded rice followed by zero till chickpea increased passive C pool (0.51%) in 0-20 cm soil depth by 42.3% than PTR-CTC (0.35%). The C fractions revealed that zero till direct seeded rice followed by zero till chickpea had a higher SOC compared to the PTR-CTC. Also, Cfrac1 (very labile pool), Cfrac3 and Cfract (non- labile pools) were higher under conservation agriculture than conventional puddled transplanted rice followed by conventional till chickpea system. The treatment zero till direct seeded rice followed by zero till chickpea resulted in a higher microbial biomass carbon at surface soil that indicated the higher microbial functions and enzymes activities under CA than CT. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | Continuous following of conventional tillage has shown degradation in soil structure and decline in crop yields. The other important issue is weed management in cropping systems. Therefore, the present finding has shown advantage over conventional practice of tillage and system based weed management. This is the need of present to sustain the agricultural production systems. |

| 7 | Any other Information: |

|

Customised fertilizers for yield maximization in chickpea

| S. No. | Title | Production Technology 8 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Customised fertilizers for yield maximization in chickpea |

| 3 | Salient feature of the Research/Technology | Due to continuous cultivation of land and use of straight fertilizers resulted in deficiency of nutrients in the soil which led to decline in productivity of crops. Thus, the use of customized fertilizers depending on crop requirement of different nutrients (major, secondary and micro-nutrients) is a way to sustain the productivity of crop. Among different combination evaluated at ICAR-IIPR, Kanpur showed best results under customized fertilizer grade N:P:K:S:Zn:Fe:B:Mo at 5.5:4.6:4.5:8.3:1.4:0.8:0.08:0.034 kg/ha suitable for chickpea |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | Dr. Ummed Singh, Senior Scientist, Division of Crop Production, Email: drummedsingh@gmail.com

Dr. C.S. Praharaj, Principal Scientist (Agronomy), ICAR-IIPR, Kanpur*; email: cspraharaj@gmail.com *Present address: ICAR-DGR, Junagarh |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | Nutrients deficiencies are most common throughout the country. The present fertilizer recommendation is based on mainly for major nutrient like NPKS. However, micronutrients like Mo, B, Fe, Zn etc are also deficient in soils which regulate the crop growth and performance. Therefore, use of customized fertilizers is need of the day. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | An increase in yield to the tune of 11% was recorded under CFG4 over that in RDF. |

| 7 | Any other Information: |

|

IIPR Mini Dal Mill (Generation 4)

| S. No. | Title | Production Technology 9 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | IIPR Mini Dal Mill (Generation 4) |

| 3 | Salient feature of the Research/Technology | IIPR Mini Dal Mill is combination of cleaner-cum-grader, emery roller, rubber-steel diskchakki mechanism and cyclone separator. Cleaned and graded grains are passed through emery roller, for pitting or scratching prior to commonly adopted pre-treatments, viz., water soaking or oil application.In this mill multi-grit size of emery / carborundum combination roller is used for pitting or scratching grain surface in first pass. Emery roller scratches the outer seed coat of grain for ease of absorption of water or oil. After treatment, conditioning for several hours followed by prolong sun drying for several days, loosens the husk. Thus, treated grains are passed through rubber-steel disk vertical chakki for dehusking and splitting in second pass. Soft dehusking, though leaves 10-15% husk over dal, butminimizes the powdering loss. For higher degree of dehusking treated grains can be passed through emery roller in second pass, but it may result into higher powdering losses. Driven by 2.0 hp single phase motor the mill has the capacity of 75-125 kg/h for different pulses. This is the fourth generation of IIPR Mini Dal Mill. The technology has been commercialized through Agrinovate India Ltd, New Delhi and being manufactured by M/s Bharat Heavy Machines, Kanpur. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | PrasoonVerma, Senior Scientist (ASPE), 8840617369, prasoon.verma@icar.gov.in;

Man Mohan Deo, Scientist (FMP), 8281255763, mm.deo@icar.gov.in; Narendra Kumar, Principal Scientist (Agronomy), 9473929876, narendra.kumar1@icar.gov.in |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | Commonly, for domestic consumption stone chakkies ae used for pulse milling and remaining produce is sold as whole grains at prices much below the MSP through chain of service providers. Installation of mini dal mills in rural areas, minimize transportation cost and handling losses. Soft dehusking and splitting method minimizes powdering and makes more dal available for human consumption. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | Installation of IIPR Mini Dal Mil in production catchments has potential for income and employment generation for farmers,rural youth and entrepreneurs. Instead of raw grains, supply of finished dal will enhance the rural income. Since 50% population still resides in rural areas, installation of such mills in rural areas will finished dal at lower prices to rural population. |

| 7 | Any other Information: |

The mill is being manufactured by M/s Bharat Heavy Machines, Kanpur. Technology is available for commercialization through Agrinovate India Ltd., New Delhi.

|

Protocols for milling of pulses in IIPR Mini Dal Mill

| S. No. | Title | Production Technology 10 |

|---|---|---|

| 1 (a) | Name of Division | Division of Crop Production |

| (b) | Name of the Institute | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2 | Title of the research & technology developed during the last five years | Protocols for milling of pulses in IIPR Mini Dal Mill |

| 3 | Salient feature of the Research/Technology | TPulses are mostly consumed as dehusked splits, in form of dal. Indian Institute of Pulses Research, Kanpur has developed a cottage scale mini dal mill to accommodate milling of all kind of pulses. Traditionally, stone chakkies were used at domestic or cottage scale pulse milling. Use of these low capacity chakkies are cumbersome and labour intensive. IIPR Mini Dal mill with capacity ranging from 75 to 125 kg/h for different pulses can be installed in production catchments to enhance milling capacity and farm income. Based on gummy substances in between seed coat and cotyledons, pulses are categorised into easy or difficult to mill kind of pulses. Protocol for milling of different pulses in IIPR Mini Dal Mill has been developed. Lentil is easy-to-mill kind of pulse; hence, emery roller can be used for husk removal without an treatment. Rubber steel disk chakki can be used for soft splitting and dehusking. Chickpea is soaked and dried before milling in the chakki. Splits of blackgram and greengram (with seed coat), fieldpea and cowpea (without seed coat) can be produced using rubber steel disks vertical chakki without any treatment. Pigeonpea, blackgram and greengram are considered as difficult-to-mill kind of pulses. Various pre-milling treatments have been developed for these pulses. Scratching or pitting of whole grains are performed using emery roller for ease of water or oil absorption by the grains, followed by prolonged sun drying for several days. Treated grains are milled in emery rollers for higher degree of dehusking or in rubber-steel disk chakki for better dal recovery. However, for cottage scale pulse milling, water soaking can be applied uniformly, hence, recommended. |

| 4 | Developed by (Name / Designation / Contact No./Email ld) | PrasoonVerma, Senior Scientist (ASPE), 8840617369, prasoon.verma@icar.gov.in;

Vaibhav Kumar, Scientist (Biochem.), 8826877458, vaibhav.kumar@icar.gov.in; Krishnashis Das, 7838868982, krishnashis.das@icar.gov.in; Man Mohan Deo, Scientist (FMP), 8281255763, mm.deo@icar.gov.in; Narendra Kumar, Principal Scientist (Agronomy),9473929876, narendra.kumar1@icar.gov.in |

| 5 | How this technology contributed to agricultural advancements of improved farmers practices | Introduction of IIPR Mini Dal Mill in rural areas have generated entrepreneurship development among farmers and rural youth. Protocols developed for pulse milling in the mill helps in optimal utilization of the unit. With a bit compromise (10-15%) husk over finished dal, higher dal recovery of protein and fibre rich dal can be obtained. It minimizes the scouring losses in form of cotyledon powder. |

| 6 | Details of Impact on farmer’s livelihood and agricultural practices: | Pulse milling protocol has been developed for milling of different pulses in IIPR Mini Dal Mill leading to income and employment generation in rural areas. Several incubates and Self-Help Groups (SHG) are producing dal using this protocols. |

| 7 | Any other Information: | The milling byproduct generated using water soaking as pretreatment can be utilized for edible purposes making ready-to-eat or-cook edible products. |

Bioactive compounds in milling byproduct of pulses and it’s edible usage

| S. No. | Title | Production Technology 11 |

|---|---|---|

| 1. (a) | Name of Division: | Division of Crop Production |

| (b) | Name of Institute: | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2. | Title of the Research & Technologies developed during the last five years: | Bioactive compounds in milling byproduct of pulses and it’s edible usage |

| 3. | Salient feature of the Research/Technology: | Pulse milling is the third largest food processing industry after wheat and rice milling. Commercially, pulses are milled in abrasive dehusking roller mills. Grains are passed over rotating emery/carborundum rollers, which causes starching of outer seed coat. Pre-milling treatments are given to loosen the seed coat for ease of husk removal. Despite pre-milling treatments, to achieve complete dehusking grains are passes multiple times through abrasive rollers. This causes scouring of outer protein rich layer of cotyledons. It gets mixed with seed coat to produce byproduct of pulses milling.The milling byproduct is used as low value cattle feed. Milling byproduct from different pulses was evaluated for bioactive compounds such as proteins, phenols, antioxidants and fibre. The results of biochemical studies of pulse milling byproduct and itsfractions,indicated that pulses milling byproduct can be utilized in developing nutritious and health ready-to-eat or cook typeedible products. Byproduct as whole can be utilized for biscuit making, whereas powder fraction separated from milling byproduct can be used as source of pulse protein in making traditional or commercial food recipes. |

| 4. | Developed by (Name/Designation/Contact No./Email Id): | PrasoonVerma, Senior Scientist (ASPE), 8840617369, prasoon.verma@icar.gov.in;

Vaibhav Kumar, Scientist (Biochemistry), 8826877458, vaibhav.kumar@icar.gov.in; Krishnashis Das, Scientist (Microbiology), 7838868982, krishnashis.das@icar.gov.in; Man Mohan Deo, Scientist (FMP), 8281255763, mm.deo@icar.gov.in; Narendra Kumar, Principal Scientist (Agronomy), 9473929876, narendra.kumar1@icar.gov.in |

| 5. | How this technology contributed to agricultural advancements or improved farmer practices: | Among various postharvest handling stages, pulses milling contributes maximum losses after storage During pulse milling, about 30% grain mass is lost inform of byproduct. The milling byproduct being rich in proteins, phenols antioxidants and fiber, can be used as an ingredient to traditional or commercial food products.Presently, byproduct is utilized as low value cattle feed. However, using milling byproduct for edible purposes will fetch better market prices. By adoption of washing and sifting systems, pulse millers can also sell pulses milling byproduct to secondary and tertiary food processing industries at higher prices. |

| 6. | Details of Impact on farmer’s livelihood and agricultural practices: | In cottage scale pulse milling, washing and soaking is essential process, which ensures removal of dust from grains. The milling byproduct, thus, obtained from mini dal mills can be used in developing proteins, phenols, antioxidants and fire rich edible products. Using it for edible purposes will fetch better market than used for cattle feed. By making value added products from milling byproduct of pulses can enhance income of cottage scale millers using IIPR or any other small capacity dal mill. |

| 7. | Any other Information: |

|

High fibre and protein rich pulse biscuits by utilizing pulse milling byproduct

| S. No. | Title | Production Technology 12 |

|---|---|---|

| 1. (a) | Name of Division: | Division of Crop Production |

| (b) | Name of Institute: | ICAR-Indian Institute of Pulses Research, Kanpur 208024, Uttar Pradesh |

| 2. | Title of the Research & Technologies developed during the last five years: | High fibre and protein rich pulse biscuits by utilizing pulse milling byproduct

|

| 3. | Salient feature of the Research/Technology: | Pulses milling byproduct was evaluated for biochemical parameters, viz., proteins, phenols, antioxidants and fibre. Being rich source of these bioactive compounds, it can be used for edible purposes, instead of low value cattle feed.The milling byproduct was grinded in hammer mill to obtained powder of uniform particle size. This was used as one of the ingredients, along with whole wheat flour, butter/hydrogenated vegetable oil, sugar, milk and leavening agents to make protein and fibre rich biscuits. These biscuits have amino acid combination of complementary proteins of cereals and pulses. |

| 4. | Developed by (Name/Designation/Contact No./Email Id): | PrasoonVerma, Senior Scientist (ASPE), 8840617369, prasoon.verma@icar.gov.in;

Vaibhav Kumar, Scientist (Biochemistry), 8826877458, vaibhav.kumar@icar.gov.in; Krishnashis Das, Scientist (Microbiology), 7838868982, krishnashis.das@icar.gov.in; Man Mohan Deo, Scientist (FMP), 8281255763, mm.deo@icar.gov.in; Narendra Kumar, Principal Scientist (Agronomy), 9473929876, narendra.kumar1@icar.gov.in |

| 5. | How this technology contributed to agricultural advancements or improved farmer practices: | Biscuits are commercial bakery product, often prepared from low fibre refined wheat flour (white flour or maida). Incorporation of pulses milling byproduct adds fibre and pulse proteins to the biscuits prepared. Use of pulses milling byproduct can be adopted in biscuits industry. Such biscuits can fetch higher market price in comparison to biscuits made from white flour. |

| 6. | Details of Impact on farmer’s livelihood and agricultural practices: | Dust free milling byproduct generated in cottage scale pulse milling can enhance income of small entrepreneurs and miller by sale of byproduct to bakery industry at higher prices compare to byproduct sold for cattle feed purposes. |

| 7. | Any other Information: |  |