Division of Crop Production

Introduction

This division comprises of major disciplines of Crop Production with a scientific strength of nine scientists. Division of Crop Production is engaged in research and extension activities related to the cropping system, integrated nutrient, water and weed management, resource conservation, organic and natural farming, agronomic bio-fortification, farm machineries and post-harvest technology.

Thrust areas:

- Long term effect of pulses in cropping systems and sustainable intensification in new niches

- Input use efficiency (water, nutrients and agro-chemicals)

- Resource Conservation Technologies and farm mechanisation

- Organic/natural farming in pulse based cropping systems

- Post-harvest management and value addition

- New agronomy (nano-fertilisers, herbicides and agronomic bio-fortification)

Theme-wise brief research achievements:

1. Diversification of Maize-wheat system with Pulses: Long term Impacts

- Pulse inclusive maize based rotation increased active and passive C-pools in soil. Pigeonpea (P)-wheat (W) and maize (M)-W-Mungbean (Mb) rotation contains maximum amount of available nutrient and soil C- pools in soil over the conventional M-W rotation. The effect of pulse inclusion was prominent on soil C and P- bioavailability.

- Pulse inclusive rotation improves soil aggregation and the effect was conspicuous in the P-W and M-W-Mb rotation. Along with this pulse inclusion improves mean weight diameter, bulk density and water holding capacity.

- All the Pulse inclusive rotation favoured C-sequestration, soil microbial biomass C (SMBC), soil enzymatic activity. Most prominent change in pulse based systems noticed in alkaline phosphatase and dehydrogenase activity.

- Inclusion of summer mung bean in the M-W system improves base crop productivity as well as system productivity. Pulses are found equally responsive in the integrated and recommended dose of fertiliser conditions.

2. Diversification of Rice-wheat system with Pulses: Long term Impacts

- Rice inclusive pulse based rotations increased active and passive C-pools in soil. Rice (R) -W-Mb had the highest positive impact on soil nutrient availability (N,P,K,S) and C-availability. The effect of pulse inclusion is also prominent in P-availability also.

- Pulse inclusive rotation improved soil aggregation and the highest change can be visible in the R-W-Mb rotation in the integrated nutrient management system.

- Pulse inclusive rotation positively impacted the C-sequestration in the macro-fractions.

- Significant impact can be visible in the SMBC and soil enzymatic activity. The most prominent action can be found in R-W-Mb followed in R-chickpea (C) system.

- Inclusion of summer mungbean improves base crop productivity (rice) as well as system productivity. In the rice based system pulses become more responsive in the INM practice.

3. Conservation agriculture for sustainable intensification

- CA in pulse based systems: CT puddled transplanted rice (CTDSR) –ZT in the post rainy season (CT-ZT) and rice-chickpea/wheat-mungbean increased rice yield by 17% and wheat by 13% than conventionally tilled rice-wheat. Pulses intensive system had superior sustainable yield index of rice by 8.1%, wheat 7.7% and chickpea by 11% than rice-wheat.

- Summer mungbean under CA in rice-wheat system: The grain yield of mungbean increased by 24.4% under zero tillage (ZT) over conventional tillage (CT). Virat had highest grain yield (1478 Kg/ha) among all the mungbean varieties. Residue retention improved mungbean yield by 9.3% over its removal. System productivity in terms of mungbean equivalent yield was higher in ZT (4232 Kg/ha), residue retention (4392 Kg/ha) and Virat (4338 Kg/ha) over CT.

- CA in rice-chickpea system: ZT puddled transplanted rice (ZTDSR) –ZT chickpea (ZTC) + residue (~CA) had higher yield (crops and system) than CT. Apart from higher net return in zero tilled system, additional benefit of Rs. 35000-40000 gained under ZTDSR-ZT system than CT.

- CA for improved soil aggregation, C-sequestration and microbial activity: Significantly higher soil aggregation (24%) was recorded in ZTDSR over CT. Rice-chickpea-mungbean (R-W-Mb) and ZT rice (ZTDSR) had 22% higher C-sequestration over CT and rice-wheat system. Soil microbial biomass carbon (SMBC) increased by ~70% in ZTDSR and pulse inclusive system over intensively cultivated CT plots.

4. Precision irrigation in pulse crops

- Chickpea: Sprinkler irrigation applied in the branch and pod development stage gave higher grain yield (16.1%), biomass (9%), harvest index (5.7%), net return (22.4%), BCR (22.8%) and productivity per day (16.4%) in comparison to sprinkler irrigation in the branching phase only.

- Pigeonpea (long duration); Two distinctive stages coinciding with peak branching stage (90-100 days) and pod development (200-210 days) have been identified as the critical stage for life saving irrigation. Drip irrigation with IW: CPE ration 0.4 found suitable for irrigating the crop.

- Lentil: Higher grain yield (12%), biomass (9.7%), harvest index (5.7%), net return (11.2%), and productivity per day (12%) were found in sprinkler irrigation applied only at branching over that in flood irrigation system. Water use efficiency (14.3%) and water productivity (12.5%) recorded with sprinkler at branching over the flood.

- Urdben and mungbean: Frequent shallow irrigation with micro sprinklers at different crop stages gave almost at par yield over normal flood irrigation. Sprinkler irrigation had 21.5% less water use with 83.5% higher WUE, WP (83%), net return (53.5%) and BCR (19.6 % and 0.61) over flood irrigation.

- Fieldpea: Higher WP (1.53 times), crop productivity (1.5 q/ha) and increased biomass along with higher pods per plant & grain weight/plant were recorded in sprinkler irrigation at branching and pod development stage.

- Hydrogel: There is no scaling in chickpea productivity or profit following application of hydrogen (even at higher dose of 5 Kg/ha).

- Salicylic acid (SA) @ 100 ppm showed advantage in respect of chickpea grain yield (22.4%), WUE (20.1%), WP (15.3%) and net return (31.2%) over water spray. Urea (2%) or NPK (0.5%) were also equally effective with that of SA 100 ppm in chickpea.

5. Agro-technologies for rainfed rice-fallow of India

I. Rice+urdbean/mungbean/lathyrus/lentil relay cropping

- Broadcasting pulses seeds 7- 10 days before rice harvest

- Use of 25% higher seed rate of pulses in relay cropping

- Seed priming (soaking the seeds for 4-6 hrs) in water and micro-nutrient solutions

- Seed treatement with fungicide, rhizobium, PSB and PGPRs

- Maintinance of 20-30 cm rice stubble on the ground to conserve soil moisture

- Foliar spray with 2% Urea/DAP, first at 50% flowering then at after 10 days

- Rice ratoon/ weed control: Quizalophop ethyl @ 50-100 g a.i./ha

- Following of IPM modules for diseases and pest management

- Use of farm ponds for water harvesting and lifesaving irrigatiobn with sprinkler

- Rice cultivation through transplanting under unpuddled condition and DSR

II. Rice- lentil/chickpea/pea sequestial cropping

- Sowing of pulses under zero tillage just after harvest of rice

- Use of medium or short duration, high yielding and multiple disease resistance pulses varieties

- Remaining practices as mentioned under relay cropping

6. Organic farming in pulses

- Significantly higher yield in wheat (5.73 t/ha) can be realized through organic practice only. Potential productivity in wheat can also be achieved following foliar supply of organic forms of Zinc (Biozinc), Phosphorus (Biophos) and vermiwash. The higher economic gain in terms of gross returns and B:C ratio (1.83) was recorded under organic cultivation compared to the conventional in green manure-wheat-mungbean cropping system.

7. Weed management in pulses

I. Weed seedbank density

- Rice-chickpea and pigeonpea-wheat system recorded significantly higher weed seed density and diversity than rice-wheat and maize-wheat system.

- Rice-chickpea system had lower field emerged weed density in rice.

II. Chemical weed management

- Kharif pulses (mungbean, urdbean and pigeonpea)-Pendimethalin 1.0 kg a.i. /ha (PRE) and Imezathapyr 100 g a.i./ ha (POST) at 20-25 DAS

- Rabi pulses (chickpea, lentil and pea)-Pendimethalin 1.0 kg a.i./ha (PRE), Quizalofop-ethyl 100 g a.i./ha (POST) at 20-25 DAS

- Spring/summer system (mungbean and urdbean)- Imezathapyr 80 g a.i./ ha (POST) at 20-25 DAS (after first irrigation)

- New post emergence herbicide– Clodinafop-propagyl + sodium aciflurofen 187.5 ml a.i./ha at 15-20 DAS in mungbean and Topramezone 20.6 ml a.i./ha at 14-21 DAS in chickpea

III. Rice-chickpea system

- Pendimethalin 1.0 kg a.i. /ha (PRE) and Bispyribac-Na 20 g a.i./ha at 20 DAS in rice

- Oxyflurofen 150 g a.i./ ha (PRE)- propaquizafop 100 g a.i./ ha (POST) at 25 DAS in chickpea.

Weed management in rice-chickpea system

IV. Ratoon management in rice fallow

- Quizalophop ethyl 100 g a.i./ha (POST) at 20-25 DAS in pulses in rice-pulse based cropping system

- Glyphosate 1.0 kg a.i./ha as pre-plant application in pulses for rice fallow condition

8. Soil P management and dynamics under pulse based system

- Plant growth parameters like Leaf chlorophyll content, nitrate reductase activity and plant biomass and others growth parameters influenced positively by 20-30% under poultry manure (1.0 t/ha) incorporation as compared to control (-P) plots.

- System productivity is higher i.e 10% (pigeonpea-wheat) and 9% (pearl millet-chickpea) with crop residue (50%) + PSB application over control.

Effect od integrated P-management on productivity of cropping system.

- P solubilisation study revealed that Cumulative P mineralization is maximum with poultry manure @ 1.0 t/ha by 34% over control and among residues pearl millet releases maximum P over others.

- Irrespective of crops overall soluble P-fraction increased in poultry manure (PM) added plots by almost 30-35% in comparison to control and significantly higher over RDF too. Adsorption study of P showed manure addition reduced adsorption maxima (Xm) because- 1. saturation of the P-adsorbtion site, 2. OC covering on oxides and carbonates..

9. Zinc accounting and enrichment in pulses

- Foliar spray at 0.5% ZnSO4 (sprayed at the pre-flowering and pod formation stage) had reported to have higher seed zinc content of 65 to 75 ppm which was 20-25% higher than control.

- Genotypes like IPC 11-112 and JG 14 had responded good for pure microbial consortium treatment and the yield obtained was on par with the foliar spray at 0.5% ZnSO

- Genotypes like JG 16, GNG 2171, IPC 10 62 and GNG 469, Vijay, GNG 2171 are soil and foliar applied zinc responsive genotypes, respectively. Whereas, Vijay, GNG 469, JAKI 9218 can utilise soil and foliar Zn efficiently.

Pre- and post-harvest mechanization and value addition

| S.No. | Particulars of the Machines | |

|---|---|---|

| 1 | IIPR Manual Zero-till drill • Labour requirement, Man-h/ha: 40 • Field capacity, ha/h: 0.05 • Cost of operation, Rs/ha : 845 |

|

| 2 | Vertical thresher : • Vertical beater & drum • Fixed cylinder-concave gap • Clamp type beaters • Multi-crop threshing • Choppers provided • Good for sturdy crops • Capacity : – Chickpea : 300 kg/h – Pigeonpea (stripped) : 450 kg/h |

|

| 3 | IIPR Pigeonpea Stripper: • Loop & pegs to remove pods from plant • Minimal loss to plant structure • Drudgery reduction • Capacity : 150 kg/h |

|

| 4 | IIPR Suction Winnower • Operator’s comfort • Suction of falling light impurities • Two stage fall • Impurities blown away from operator • Capacity : 150 kg/h |

|

| 5 | IIPR Dal Chakki : • Rubber-steel disk mechanism • Auger feed system • Cyclone separator • Pre-treatment – water soaking • Capacity : 75-125 kg/h |

|

| 6 | IIPR Mini Dal Mill • Emery roller for pitting • Grader for raw and finished product • Rubber-steel disk for dehusking& splitting • Auger feed system & Cyclone separator • Pre-treatment – Oil & water soaking • Capacity : 75-125 kg/h |

|

| 7 | IIPR Multi-purpose Grinder Main features :

•Used for making ‘besan’ from chickpea, flour and grinding spices

|

|

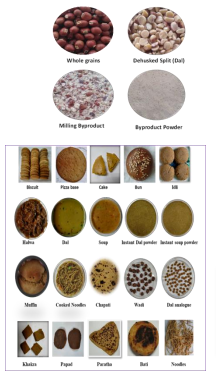

Utilization of pulses milling byproduct for edible use

- Pulses are consumed after dehusking and splitting, in form of dal. The byproduct obtained during the milling process is rich in bioactive compounds, viz., protein, fibre, phenol, anticarcinogenic compounds and antioxidants. These milling byproducts can be used for making many edible food products.

- Husk component therapeutic values are mainly antioxidant activity, polyphenolic compounds and fibers

- Powder component (Pulse Protein) can be used for making pulse based recipes including bakery products.

Technologies available for commercialization

- 1. IIPR Dal Chakki

- 2. IIPR Mini Dal Mill

- 3. Pulse Threshing and Allied Machinesi) IIPR Vertical Thresher<

ii) IIPR Pigeonpea Stripper

iii) IIPR Suction Winnower - 4. Multipurpose grinder

- 5. Hand operated vertical dal chakki

- 6. Hand operated horizontal dal chakki

- 7. Utilization of pulse milling byproducts for edible use – Protein & Fiber Rich Biscuits

- 8. Utilization of pulse milling byproducts for edible use – Dal Analogue

- 9. Utilization of pulse milling byproducts for edible use – Pizza Base

- 10. Utilization of pulse milling byproducts for edible use – Bun.

- 11. Utilization of pulse milling byproducts for edible use – Cakes and Muffins

- 12. Utilization of pulse milling byproducts for edible use – Noodles

- 13. Utilization of pulse milling byproducts for edible use – Instant Pulse Soup

- 14. Utilization of pulse milling byproducts for edible use – Instant Dal

- 15. Utilization of pulse mill ing byproducts for edible use – Flour (Atta) Mix

- 16. Utilization of pulse milling byproducts for edible use – Sattu

- 17. Utilization of pulse milling byproducts for edible use – Nachos

- 18. Protocols for milling of pulses in IIPR Mini Dal Mill

- 19.Mechanical manual weeder with multi-tool bar carrier

- 20. Roller contact type herbicide applicator

On-going research projects:

| S.No. | Title of the project | Principal Investigator |

|---|---|---|

| Programme 1. Development of Climate Smart Agro-technologies for Pulses under Diversified Agro-ecological Regions of India

Coordinator/PI: Dr. Narendra Kumar |

||

| 1 | Long-term effect of pulses in existing rice-wheat cropping systems on soil health and crop productivity under Gangetic Plains | Dr. Narendra Kumar |

| 2 | Development of conservation practices in pulse production systems for production-cost reduction and higher productivity under changing climate | Dr. Narendra Kumar |

| 3 | Precision irrigation scheduling for higher productivity and input use efficiency in pulses based cropping systems (including evaluation of new Varieties) | Dr. K.K. Hazra |

| 4 | Sustainable intensification of rice fallows with inclusion of pulses in Eastern India | Dr. K.K. Hazra |

| 5 | Organic farming in pulses and its cropping system with technological interventions in Gangetic Plains | Dr. Md. Hashim |

| 6 | Developing climate-resilient agro-technologies to alleviate nutrient and abiotic stresses in pulses | Dr. K. K. Hazra |

| 7 | Designing weed and input management practices in pulses and conservation agriculture system for sustainable production and ecosystem services | Dr. C.P. Nath |

| 8 | Soil phosphorus dynamics and its release kinetics under pulse based cropping system for sustainable P management in an Inceptisol | Mr. Asik Dutta |

| 9 | Zinc accounting and enrichment in pulses through integrated crop management practices | Dr. K. Mrunalini |

| 10 | Farm mechanization suitable for pulses and its cropping system in Gangetic Plains | Dr. Man Mohan Deo |

| 11. | Development of Pulses-based Natural Farming System for Enhancing the Sustainability of Ecosystem | Dr. Md. Hashim |

| 12. | Adoption, refinement, and development of farm machineries for pulses for small and marginal farmers | Dr. Man Mohan Deo |

| 13. | Development of novel coated P-fertilisers for increasing PUE and system productivity under cereal-pulse cropping system in an Inceptisol | Mr. Asik Dutta |

| 14. | Enhancing nutrient use efficiency, productivity and profitability of pulses through Nano- fertilizers | Dr. Mohammad Hashim |

| Programme 2: Post harvest management of pulses, value addition and byproduct utilization

Coordinator/PI: Dr. Prasoon Verma |

||

| 1. | Evaluation of existing pre-milling treatments and development of improved pre-milling treatments for ease of pulse milling | Dr. Prasoon Verma |

| 2. | Processing of pulse seeds and development of methods for their long term storage | Dr. Prasoon Verma |

| 3. | Determination of emery grit sizes for different pulses | Dr. Prasoon Verma |

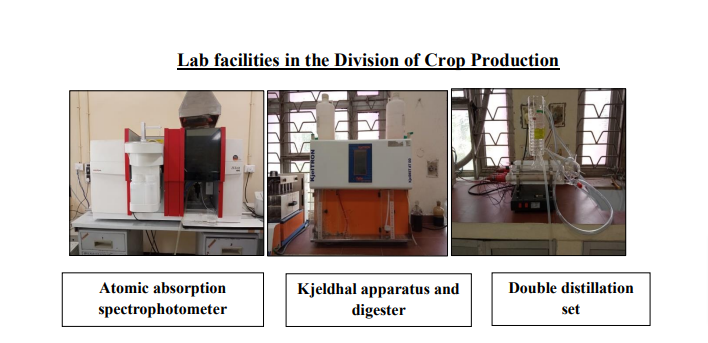

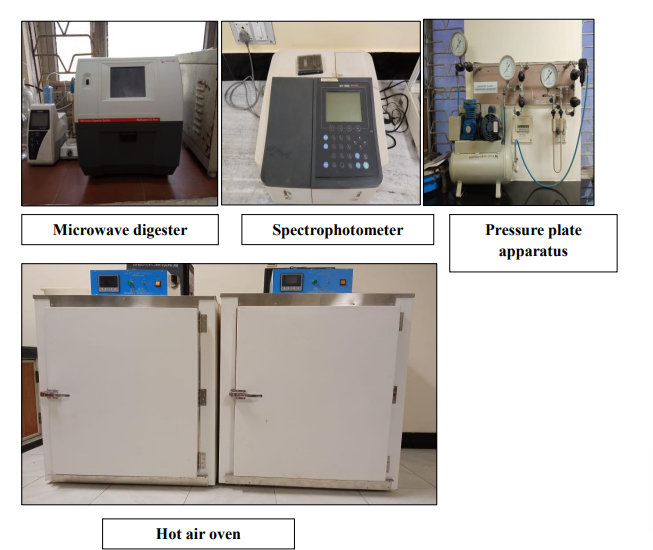

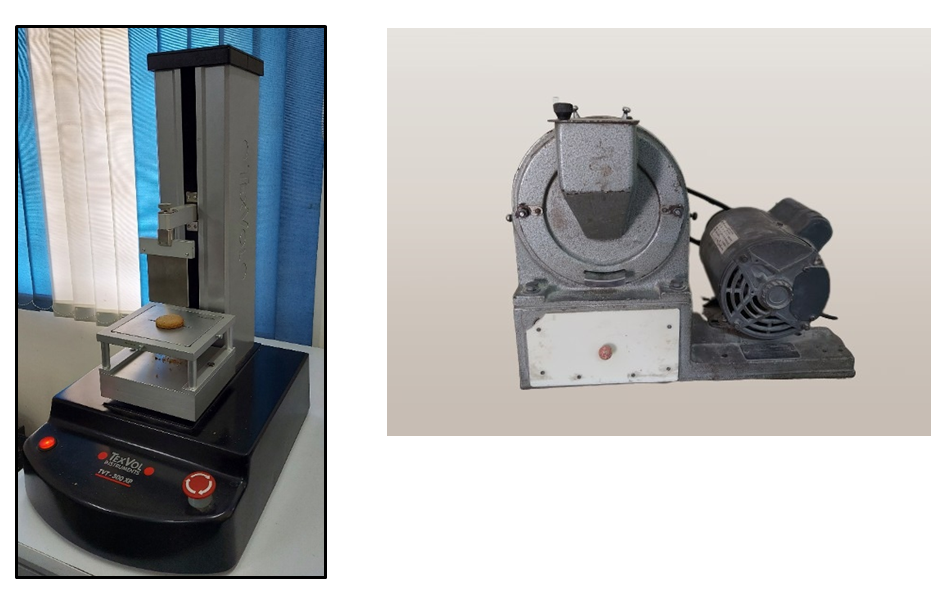

Texture analyzer

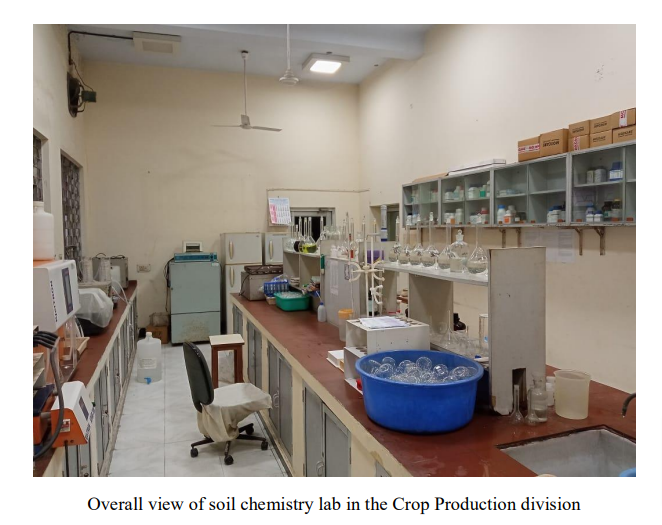

Pulses processing complex in the Crop Production division

Scientists and their area of specialization